Artificial Separations

When vessels are scheduled to load multiple grades of the same commodity or different commodities altogether then some form of separation is typically required. Natural hold separation is certainly the most ideal type as there are no extra costs associated (aside from the possibility of the vessel not being to lift their maximum cargo intake) and there is no chance of contamination between the grades/commodities. When natural separation is not possible or economical, then the need for an artificial separation is required. This involves building a separation using artificial materials which contain a mix of oriented strand board and poly cloth. There are two types of separations that are commonly built along the West Coast of Canada: full oriented strand board style (i.e. Kobe style) and crash pad style separations.

When vessels are scheduled to load multiple grades of the same commodity or different commodities altogether then some form of separation is typically required. Natural hold separation is certainly the most ideal type as there are no extra costs associated (aside from the possibility of the vessel not being to lift their maximum cargo intake) and there is no chance of contamination between the grades/commodities. When natural separation is not possible or economical, then the need for an artificial separation is required. This involves building a separation using artificial materials which contain a mix of oriented strand board and poly cloth. There are two types of separations that are commonly built along the West Coast of Canada: full oriented strand board style (i.e. Kobe style) and crash pad style separations.

OSB separations are by far the most common type of artificial separation as the chances of cross contamination between the two cargoes is minimized. In this process, the lower part of the hold is loaded with whichever cargo needs to be discharged off the vessel last. Often times, the suppliers will order a second labour gang to build the separation while loading continues in another hold to avoid delays in loading operations. To prepare the hold for the separation, longshoremen will drop a bombardier into the hold to level the cargo and ensure it is flat. Additional labourers will then hand shovel some of the harder to reach areas to make everything as even keel as possible. Once complete, the poly cloth is laid flat across the entire cargo with all corners and edges sealed with rib fillers. The rib fillers are then held down with smaller pieces of OSB board for further security. Finally, a full floor of OSB board is laid down onto the hold. Each piece overlaps the other at each side by about 6-10 inches. See the above photo for an example of this style of separation.

Alternatively, the process for a crash pad style separation is slightly less intensive. The initial process remains the same whereby a bombardier is used to level the cargo followed by hand levelling with shovels. The poly cloth is once again laid flat with the corners and edges sealed with rib fillers and secured with small OSB pieces. Where the two separations differ is that only the area under the hatch square is covered in OSB board as opposed to the entire hold. Because less OSB boards are required, the crash pad style is typically less costly than the full OSB style.

The above processes can be further complicated if fumigation needs to occur for the cargo on the bottom. In this case, recirculation piping will be pre-installed in the bottom of the hold prior to loading so that the fumigators are able to safely apply the fumigant after the separation has been built. If the top portion of the hold needs to be fumigated as well, regular fumigation methods can be used afterwards. Another method involves the cutting of holes/openings into the OSB boards to allow the fumigant to successfully permeate through the separation. The poly cloth is left undisturbed to ensure the cargoes are still safely separated. The holes that need to be cut have to be done so in a specific pattern and with certain measurements.

Finally, there can be some logistics involved in getting the separation materials safely on board (including the bombardier). If the terminal permits (not all do), then the materials and equipment can be loaded shore side using the vessel’s cranes (including bombardier). Longshoremen can be quite tedious in checking the crane’s certificates and overall condition before use so it is important for the vessel to ensure all required paper work/certification is in order. For terminals that do not allow this, a barge would be required to tie up on the water side with the equipment/materials which are then loaded on board. In a worst-case scenario, the terminal does not allow the vessel to stay along the berth then the vessel would shift to a local anchorage and the equipment would be barged to the vessel along with the longshoremen to build it there. To add a little more complication, weather can and often will impede progress as the hold would have to remain shut during periods of rain which can cause significant delays.

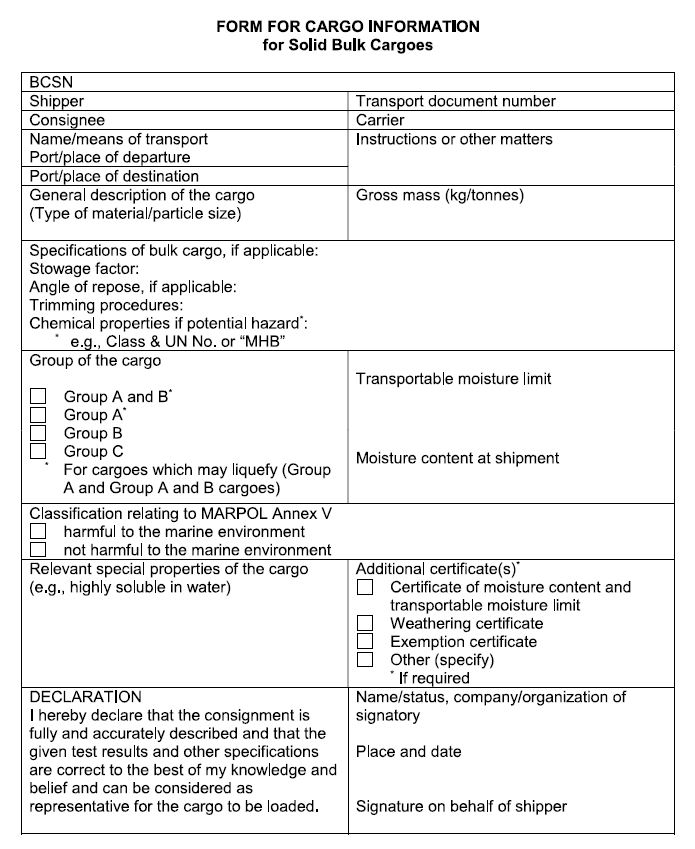

The “shipper’s declaration” or “cargo declaration” as it is often known, is a document prepared by the shippers of a cargo and presented to the Master prior to any loading operations. For grain specific cargoes, this document is quite important as it has some information on it that Transport Canada requires in order to review the grain stability calculations and grant the vessel a “Readiness to Load Grain Certificate.”

The “shipper’s declaration” or “cargo declaration” as it is often known, is a document prepared by the shippers of a cargo and presented to the Master prior to any loading operations. For grain specific cargoes, this document is quite important as it has some information on it that Transport Canada requires in order to review the grain stability calculations and grant the vessel a “Readiness to Load Grain Certificate.”

s pertaining to the fumigation procedures for grain vessels. Certainly, these questions are founded as the costs involved for a vessel to fumigate on completion of loading are not inconsequential. There are two authorities involved in regulating fumigation procedures in Canada; Transport Canada and Health Canada. Transport Canada concerns themselves with the responsibilities of each involved party and the safe management of hazards to the vessel.

s pertaining to the fumigation procedures for grain vessels. Certainly, these questions are founded as the costs involved for a vessel to fumigate on completion of loading are not inconsequential. There are two authorities involved in regulating fumigation procedures in Canada; Transport Canada and Health Canada. Transport Canada concerns themselves with the responsibilities of each involved party and the safe management of hazards to the vessel.